3 & 5 Gallon Bottling Equipment

Three to five gallon bottles are highly demanded reusable options to consider for your water bottle manufacturing business. As the need for water dispensers in homes, schools, and businesses continues to grow as healthy lifestyles are publicized, the bottled water delivery industry is a great option. The value of the reusable water bottle market is projected to grow from the current size of 9.2 billion (2023) to almost $13.5 billion by 2033.

Norland’s three and five gallon bottle filling equipment is perfect for your large water bottle packaging needs. Norland International offers everything from manual to fully automated water equipment, water bottle cleaning and filling lines, to bottle racking systems. Be sure to visit our Complete Plants for more information on turnkey Large Bottling Equipment.

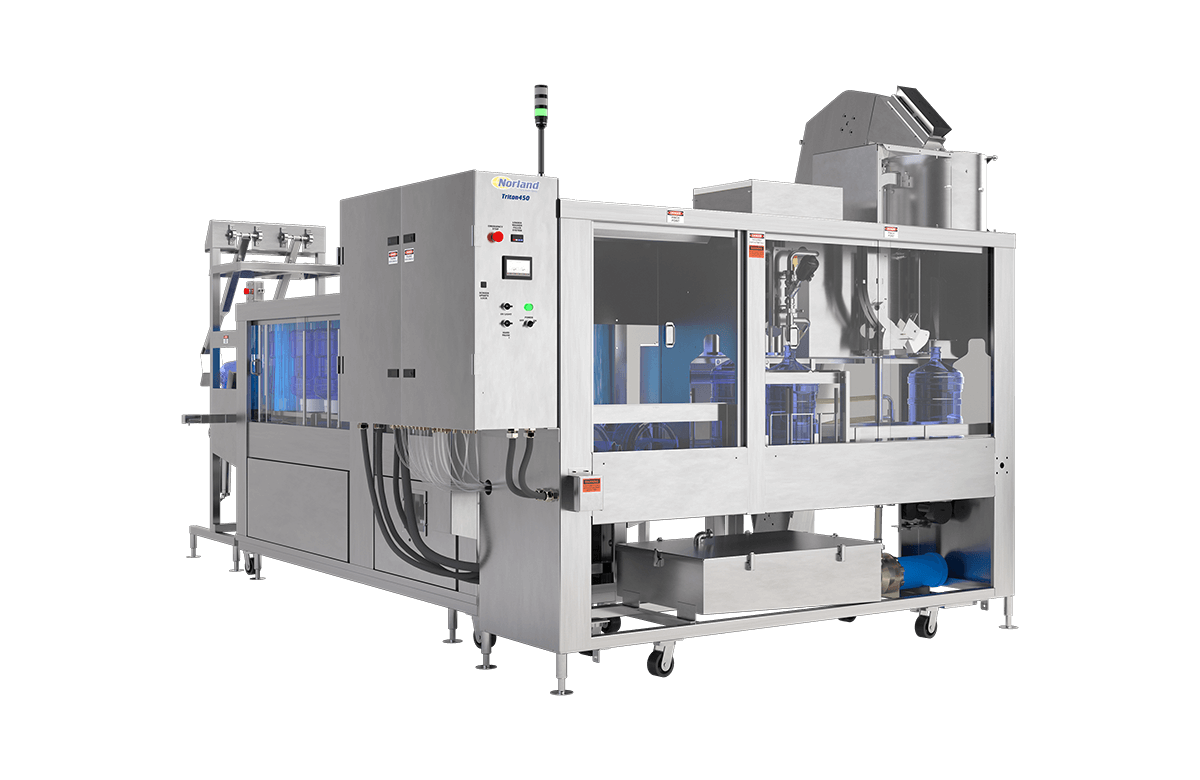

Triton450 Water Filling Machine

All-in-One Bottling System

- Pre-wash, wash, sanitize stations

- Includes large water bottle capper

- Both washer and filler operate with same electrical connection

- Injection pump for sanitizer and detergent

- Built-in water heaters

Ease-Of-Operation

- Dual bottle load system

- Different sizes can be loaded simultaneously & without changeover

- PLC controlled system allows for easy programming

- Oversized filter screens minimize screen cleaning, reducing downtime

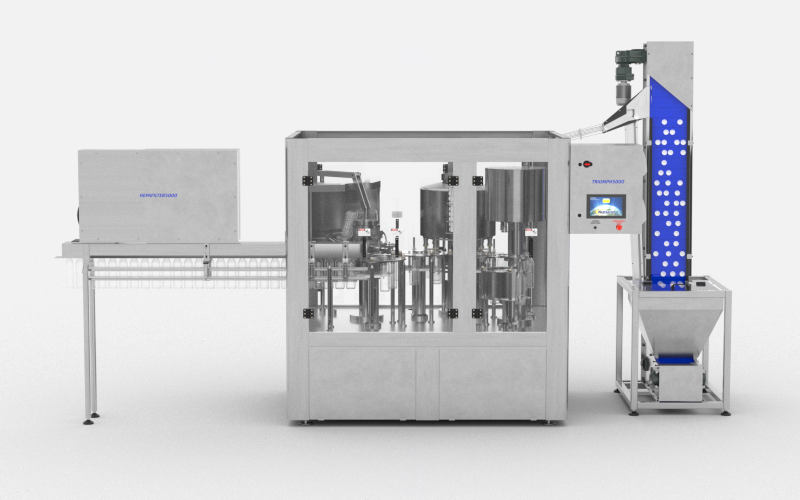

Triton160 Water Filling Machine

All-in-One Bottle Equipment

- Separate bottle washing, sanitizing & bottle rinsing machine

- High-pressure pre-wash sanitizes and removes debris

- Height sensors on both fill heads maximize production

- Built-in water heaters

- Cap hopper holds up to 50 caps

- UV light property disinfects caps

Intuitive Design

- Only one-operator needed

- Lift & Spin feature enhances cleaning inside and out

- HMI touch screen with easy programmable set-up functions

- No changeover necessary when switching bottle sizes

- Small footprint ideal for space limitations

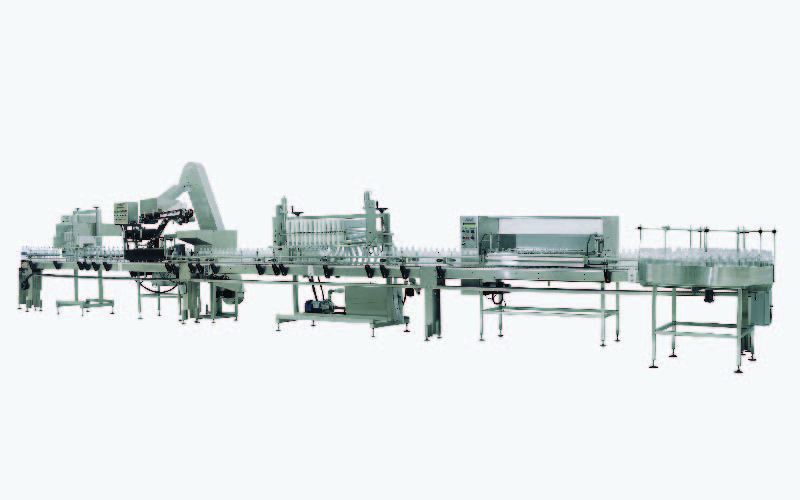

BWF150 Bottling Line

Economical Design

- Wash, fill & cap 3 and 5 gallon bottles

- Wash and sanitize solutions are recirculated for maximum efficiency

- Internal heating elements

- Precise temperature and timing controls

Versatile & Compact

- Optional small bottle system adaption

- Adjustable filling table height

- Pneumatically driven capper

- Stainless steel construction

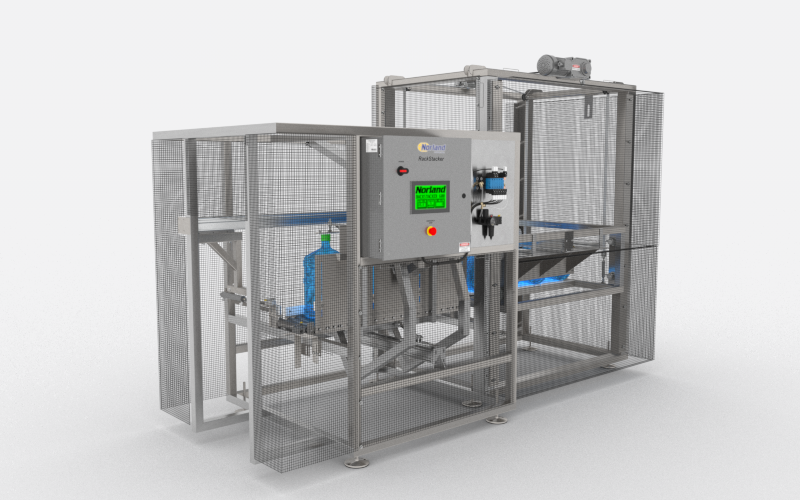

RackStacker Bottle Racking System

Increases Efficiency

- Eliminates manual lifting of 3 & 5 gallon bottles

- Labor-saving for operators

- Engineered with a proprietary alignment system

- Optional remote start

Compatible Design

- Programmable with up to 3 different rack styles

- Easily integrates in current production line

- Set up with conveyors to easily move bottles

- Automatic rack loading system option available

Five & Three Gallon Caps

Secure Fit

- Designed to snugly fit standard 3-gallon and 5-gallon jugs

- Leak-Proof Design

- Easy Installation and removal

High Quality

- Caps are digitally inspected to ensure the highest quality

- Tamper-evident option provides extra security

- Puncture or plug style available

Complete Plants

Complete Plants  Water Treatment & Purification

Water Treatment & Purification  Small Bottling Equipment (300ml-2l)

Small Bottling Equipment (300ml-2l)