Small Water Bottling Equipment

Norland International offers a diverse portfolio of beverage equipment for single-use containers, generally referred to as PET bottles. Small single-use water bottles are not only a staple in many parts of the world but continue to have a small environmental footprint. Read more about the global need for water here.

Norland International offers both fully automated water equipment solutions and manual options depending on the bottling line. Norland’s bottling equipment, PET Blow Molders, and other water-filling machines are suitable for any size of bottled water operation. Sold singularly or as a complete plant, these water systems are built for easy operation and are energy-efficient. Our experienced team can point you in the right direction, depending on your space, budget, and business model. Whether you need to blow bottles, a complete water bottling system or water bottle packaging, trust us as your water bottle manufacturing partner.

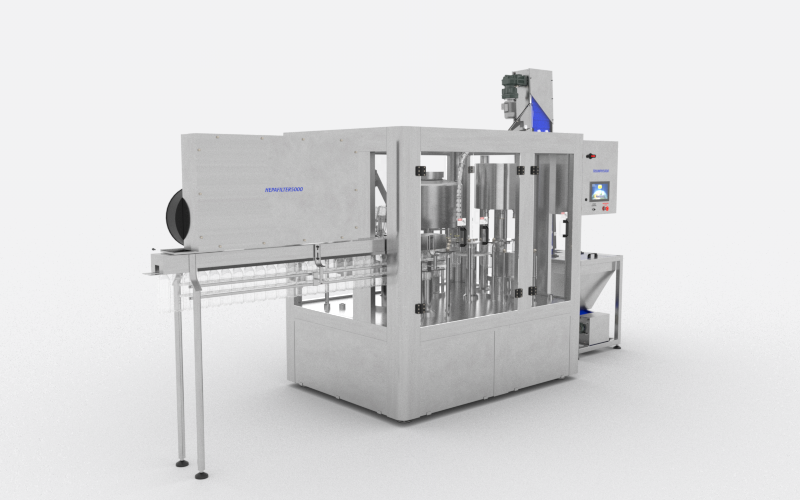

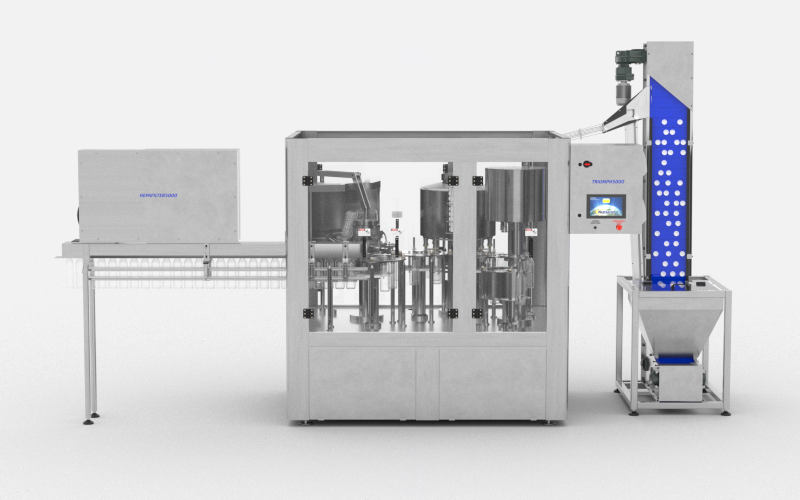

Triumph Bottling Systems

All-in-One Bottling System

- Bottle rinsing machine, bottle filling machine, and bottle capping machine all in one

- Bottle Capper can utilize 28 mm, 28 mm child-proof, or 38 mm caps

- HEPA filter comes standard on all bottling lines for sale

- Built-in clean room

- Suitable beverage filling equipment for products other than water

Speed & Efficiency

- Automatic Bottle Filler for up to 2,000 – 5,000 BPH (based on 16.9 oz bottle)

- Rinsing and spraying consume less than 1 GPM of water

- Triumph Ultra uses 18 rinse valves, 18 fill heads, and 6 cap heads

- Triumph Classic uses 8 rinse valves, 8 fill heads, and 4 cap heads

- Rotary Filling Design

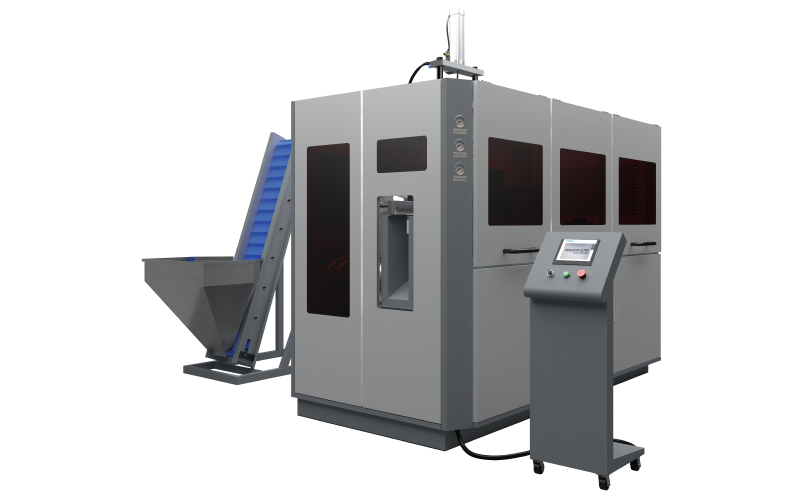

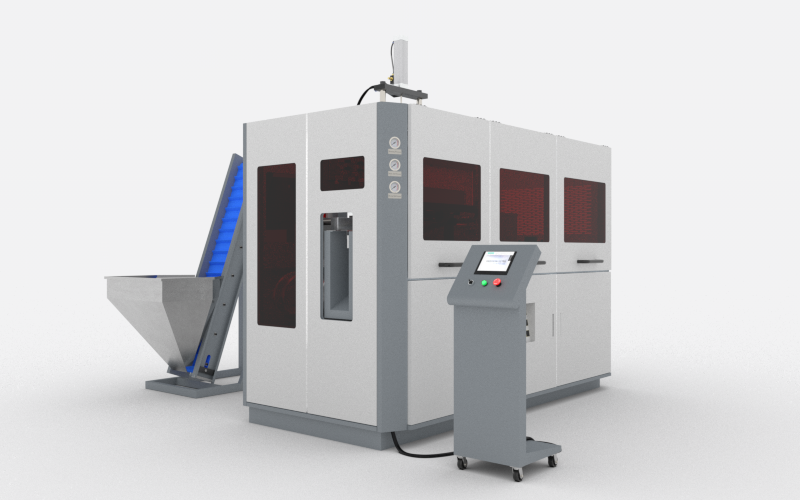

Freedom Series Blow Molders

Compact Design

- Three or five cavity chamber

- Infrared Heat Tunnel System

- HEPA filter comes standard

- Four heating zones

Efficient System

- Produces 3,000 to 5,000 BPH

- 350 ml – 1.5 liter bottle size

- PLC controlled system

- Preform elevator system

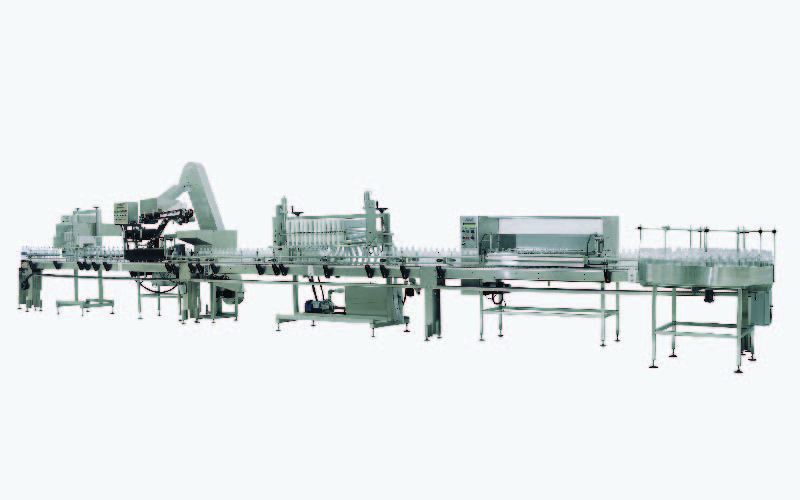

Gravity Fill Bottling Lines

- Specialty equipment designed for 300ml to 5.0 liter

- Capable of 40 or 80 bpm

- Simple to Operate

- Hot or Cold fill with temps up to 194 degrees

In-Line Solution

Complete Inline Machines Include

- Loading Table

- Bottling Rinser

- Bottling Filler

- Capping Machine

- Date Coder

- Pack-off Table/ShrinkPak

Optimal Usages

- Ideal for a variety of package formats and sizes

- Capable of filling a variety of non-carbonated beverages

- Budget-friendly solution for startups

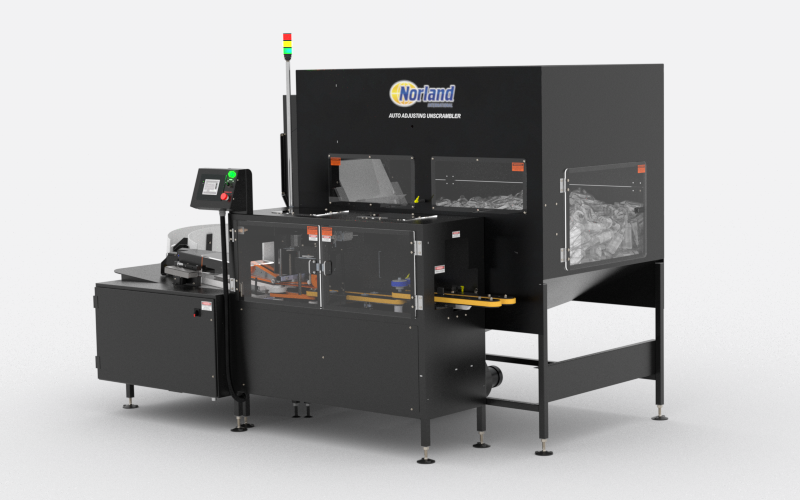

Liberty150 Automatic Bottle Unscrambler

Convenient Design

- Compatible with low to high-speed bottling lines

- Large bottle hopper with easy access

- Stack lighting to show operating conditions

- Non-lubricating drive motors

- Electronic variable speed controls

Dependable Operation

- Smooth, quiet operation with speeds up to 150 BPM (9,000 BPH)

- Few moving parts for minimum maintenance

- Electronic bottle counter and production reporting

- Automatic size adjustment (no changeover)

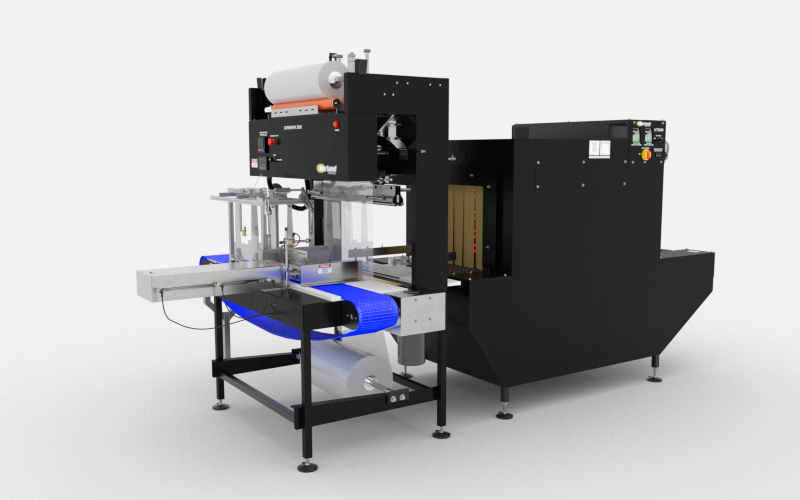

ShrinkPak Shrink Wrap Machine

Efficient Design

- Package up to 330 cases per hour

- PLC interface display with digital controls

- Manual or automatic bottle-loading options

- Can package virtually any shape or size of package

- Polyethylene film seals package from debris

VC Water Distillation Systems

VC Water Distillation Systems  Triumph Systems

Triumph Systems