Beverage Filling Lines

Norland International is renowned in the water industry for creating high-quality equipment at competitive prices and providing superior customer service. In addition to the water industry, Norland has focused on extending our range of specialty equipment products to clients throughout other markets, including beverage filling equipment. This has been made possible by ABE Equipment – a separate division of Norland International that shares the same facilities, workforce, and guiding principles. This powerhouse of knowledge and experience provides customers with exactly what they need regarding beverage packaging equipment. Read more about our bottling lines and canning equipment below.

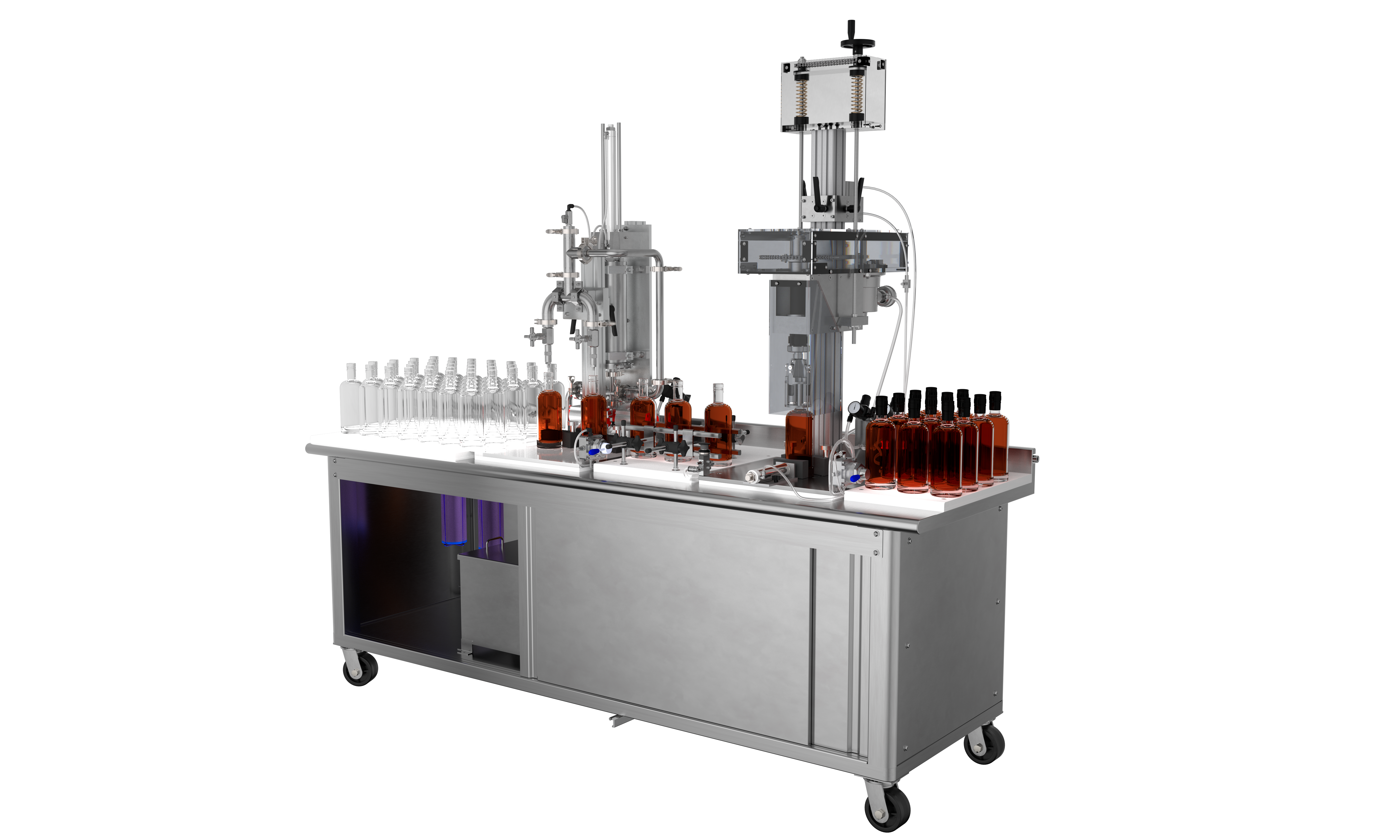

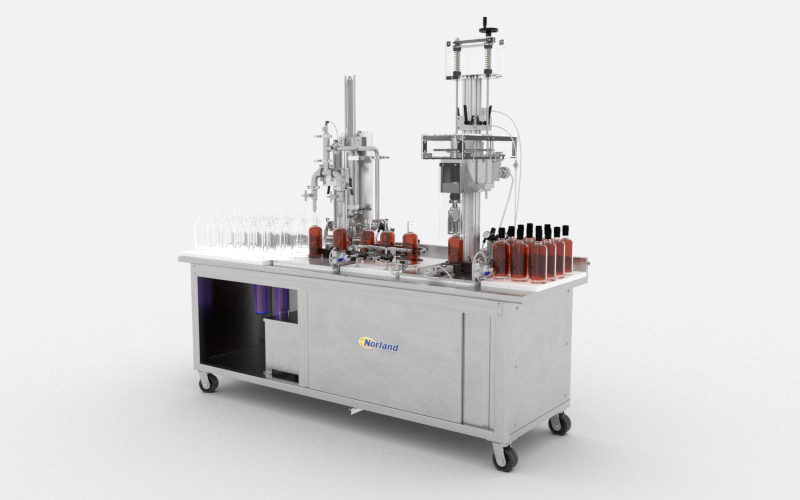

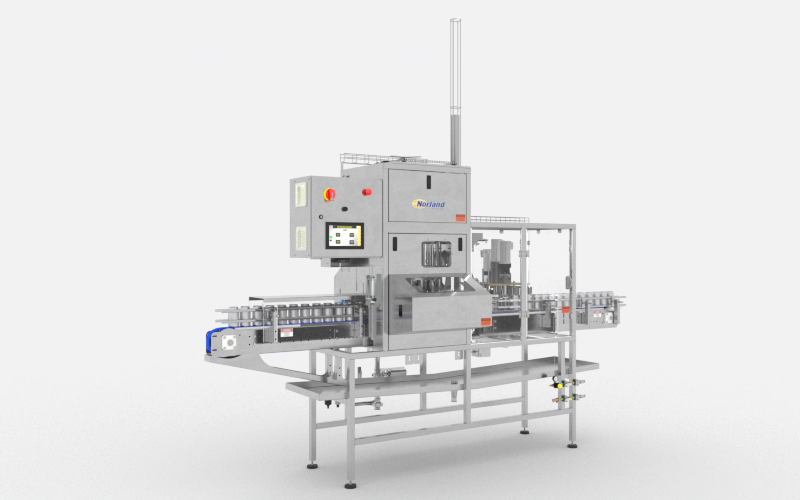

TruPatriot Bottle Filler

Volumetric Piston Filler

- Pneumatic operation – no electrical needed

- Fill up to 10 BPM/750 ml

- Accurate within <1% of volume

- Fill bottles ranging in size from 350 ml – 2.25 liter

Corking/Capping

- Interchangeable capping options are available

- ROPP (Roll on Pilfer Proof) 18-38 mm

- Corks – silicone or natural

- 28/38 mm PCO (Plastic Closure Only)

- Crown caps

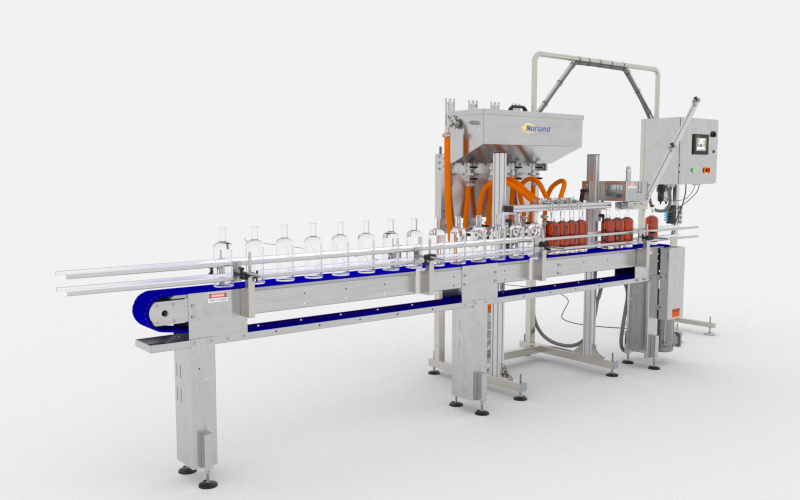

Patriot Fill Station

2-Head Bottle Filler

- Pneumatic operation – no electrical available

- Fill up to 8 BPM/750 ml

- Accurate within <1% of volume

- Fill bottles ranging in size from 12 oz to 2.25 liter

- Inquire about our alternate configurations!

Filtration Station

- A wide variety of filter options are available

- Stainless steel transfer tank with a sealed lid

- Stainless steel sanitary connections

CraftCan Series

Precision Filling

- Exclusive one-piece fill head design for enhanced sanitary environment & increased fill level accuracy

- Proprietary CO2 micro-burst action to better manage foam

- Purge cycle – precision purge control means reduced dissolved oxygen pickup resulting in reliable oxygen evacuation

Servo Seamer Technology

- Patented torque monitor instantly inspects and assesses seam accuracy on every can

- System diagnostics available for remote troubleshooting

CraftCan Duo Series

Speed and Precision

- Built-in CO2 ports on one-piece stainless steel fill heads

- Rotary-can-indexing with on-screen micro-adjustments for precise can seam positioning

- The proprietary recipe recall feature reduces setup time

Servo Seamer Technology

- Patented toque monitor instantly inspects and assesses seam accuracy on every can

- System diagnostics available for remote troubleshooting

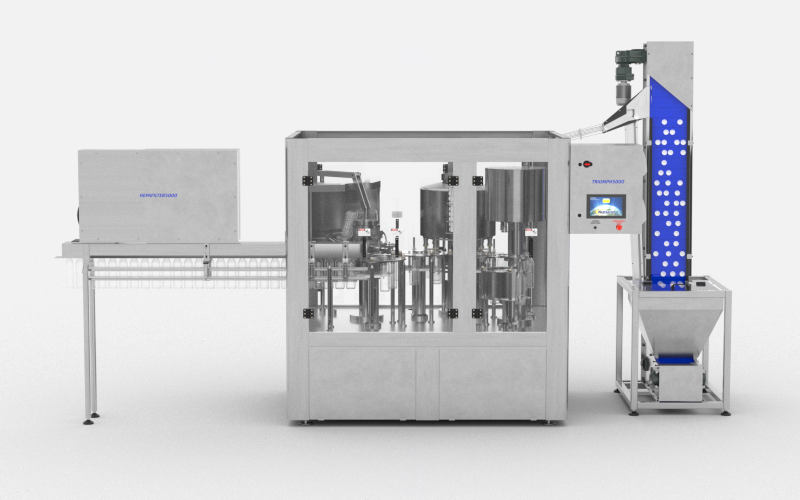

CraftCan Iso Series

Pressure Filling Technology

- CO2 Nitrogen pre-purge for reliable oxygen evacuation

- External CIP hookups with internal CIP spray balls

- Isobaric filler for beverages up to 4.0 volumes of CO2

- PLC touchscreen operation with fully adjustable cycle times

Easy Can Size Changeover

- Changing volume and diameter be done in minutes

- No special tools required

CraftCan Go Canning Line

Precise Counter-Pressure Filling

- CO2 and Nitrogen pre-purge for reliable oxygen evacuation

- Fills beverages up to 4.0 volumes of CO2

- Easily swapped with the atmospheric fill heads

Precise Atmospheric Filling

- Proprietary CO2 micro-burst action to better manage foam

- Average DO pickup: 15-25 PPB

- Nitrogen compatible

- Easily swapped with the counter pressure filling unit

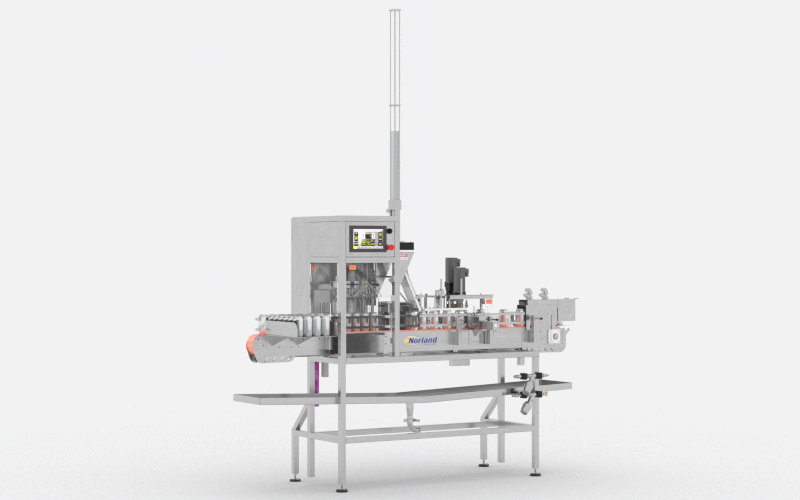

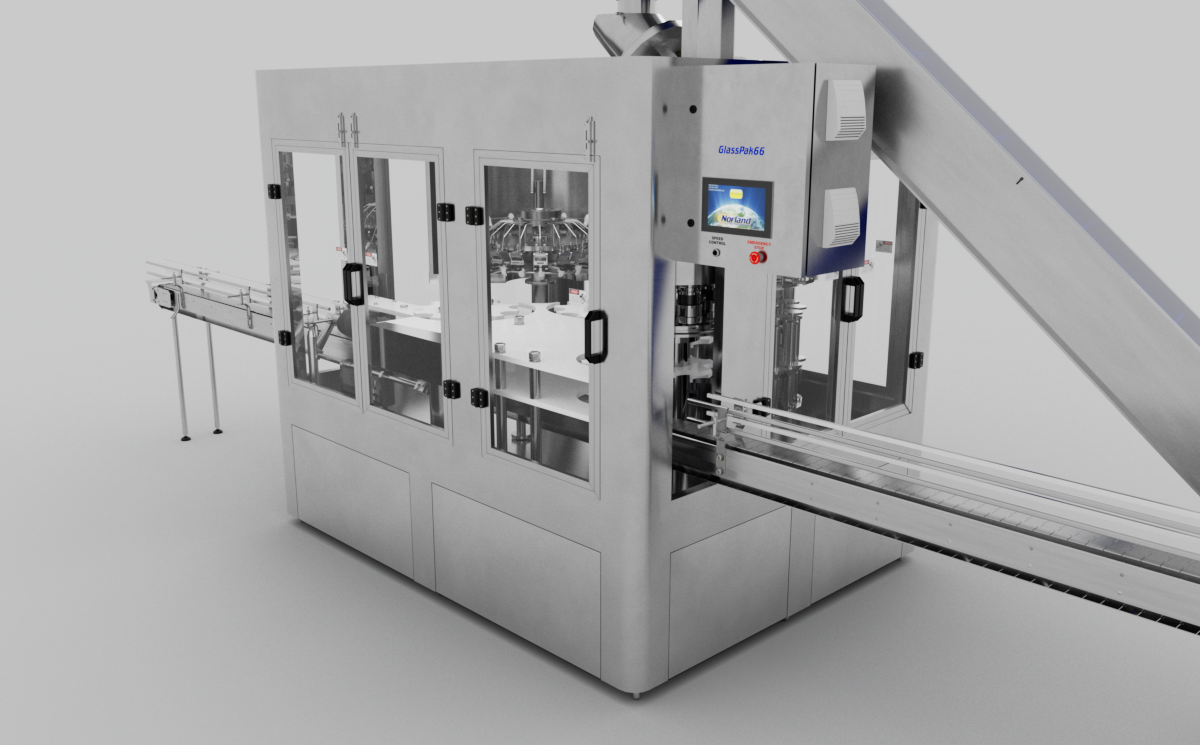

GlassPak Systems

Designed for Ease of Use

- Mono-block rotary design

- Rinses, fills, and caps

- Compatible with a variety of bottles and caps

- CIP compatible

- Nitro option available

Intuitive Features

- 10″ Color touchscreen HMI

- Remote diagnostics and monitoring

- Programmable logic controller

- Optional rinse and dry station

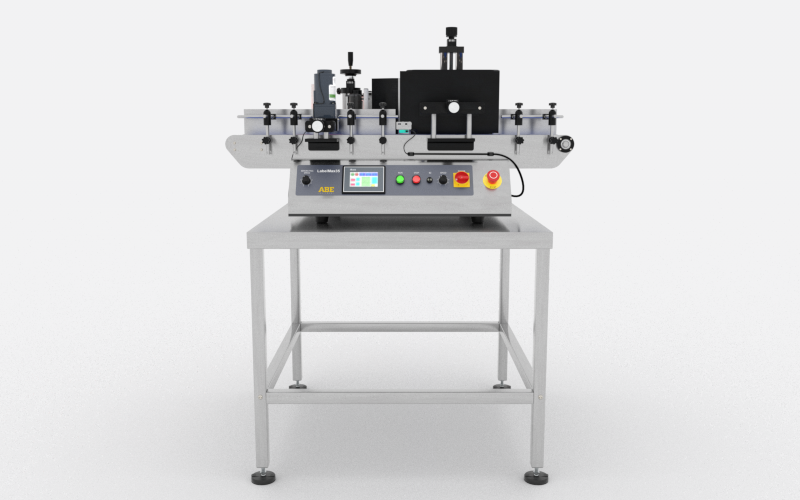

LabelMax90

LabelMax90  LabelMax35

LabelMax35  Small Bottling Equipment (300ml-2l)

Small Bottling Equipment (300ml-2l)